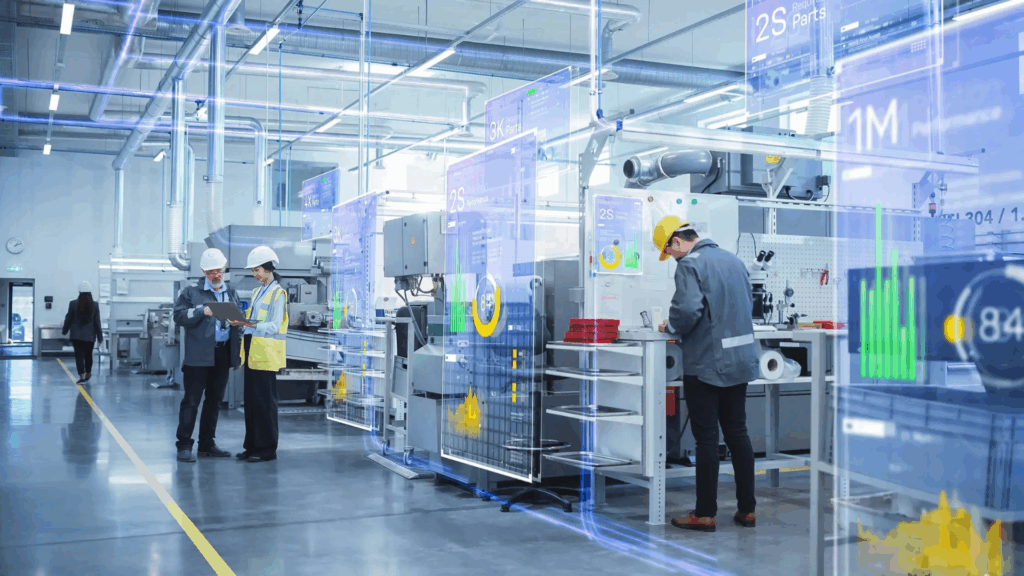

In today’s fast-paced business environment, speed, accuracy, and efficiency are critical for success in both logistics and manufacturing. Whether it’s warehouse management, shipping, or production lines, companies need reliable systems for object tracking, product counting, and automated operational analysis.

This is where MonitEye’s AI-powered computer vision technology provides a game-changing advantage.

Real-Time Object Tracking for Full Visibility

MonitEye enables companies to track objects in real time using camera-integrated AI systems. This ensures:

- Early detection of misplaced products,

- Prevention of incorrect loading or shipping,

- Optimization of warehouse layout and inventory flow.

With MonitEye, businesses gain complete visibility across their logistics and production processes.

Automated Counting and Verification

Manual counting is not only time-consuming but also prone to errors. MonitEye’s automated counting module, powered by barcode recognition and visual analysis, allows companies to:

- Verify shelf and warehouse product quantities,

- Detect missing or excess products on production lines,

- Accelerate inventory management processes.

This reduces operational costs and minimizes human error.

Intelligent Operational Analysis

Beyond tracking and counting, MonitEye delivers smart insights into operational efficiency:

- Real-time workforce and productivity measurement,

- Detection of delays and downtime,

- Identification of process bottlenecks.

With these insights, companies can create a more efficient workflow and optimize resource allocation.

Multi-Camera and Integrated Monitoring

One of MonitEye’s key strengths is its ability to work with multiple cameras simultaneously. Large warehouses and manufacturing plants can monitor several areas at once, while the system aggregates data into a centralized platform for analysis and reporting.

Driving Digital Transformation in Logistics and Manufacturing

Automating logistics operations and manufacturing workflows is not the future—it’s the present. With MonitEye, companies benefit from:

- Reduced operational risks,

- Optimized workforce distribution,

- Significant time and cost savings.

In short, MonitEye empowers businesses not only with enhanced security but also with operational excellence.